The kitchen countertop - from production to your home!

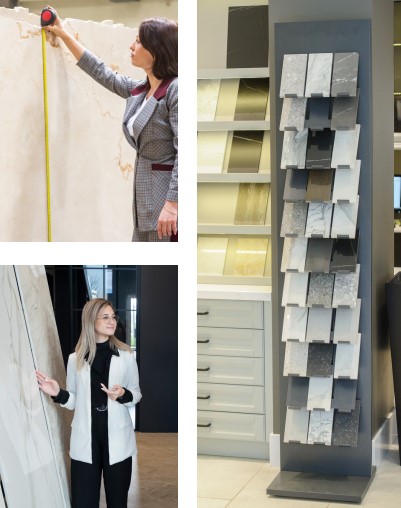

Choosing the right countertop makes all the difference when it comes to the design of your home. Carefully chosen, carefully cut and installed with soul, it will increase the value of the house.

The journey a countertop takes to reach your home takes approximately 2-4 weeks from measurements to installation. The execution time depends on the complexity of the work. Next, we propose to walk you through the steps that a tabletop follows virtually!

The first and most important is the technological analysis of the project and the calculation. This is a stage in which we determine the cost and production time of the order, all the technical data are determined and the right material is chosen for your work.

The second stage is proliner measurements. We have the most efficient machine for taking dimensions, the Proliner, and internationally qualified specialists. The Proliner allows us to measure curved, straight and very complex shapes, as well as any objects in a vertical, horizontal or inclined position. The digital drawing is then used to operate CNC machines with numerical control. With us you can be sure that your project will comply 100% with the rule of accuracy and precision.

The third stage, the most important, is production. Once the material and shade of the plate for the project is determined it is reserved and indexed in the warehouse to be delivered to production once the measurement team ships the digital blueprint of the project. Then, the stone assigned to the project is delivered in production to the appropriate machines. The human factor is very important in the stone processing phase. That is why the Art Granit team is constantly evaluated and trained by international stone processing experts. This is the only way we can ensure that level of quality that is hidden in the details and exceed our customers' expectations. We would like to mention that the cutting and processing is performed automatically, we have the most efficient machines in Eastern Europe, which ensure maximum precision, perfect finishes and record time for orders.

The fourth stage is quality control. Every order until it leaves the production hall will necessarily also pass through the quality control hall. The given process is carried out by 2 specialists, who, with the project in hand, physically check the detail, namely that it matches the color and contains all the technical requirements of the project. If a non-conformity is detected in the order, it is returned to production for remaking or adjustment. The order that has passed the quality control is accompanied by the confirmatory documents and only after that it goes to the next stage, namely to the logistics department.

In the logistics department, the planning of the delivery and installation of the countertop takes place, which is the 5th stage. The logistics department is the one who plans the installation, depending on the schedule and the availability of the customer to welcome us to the installation. The next link is the delivery and installation, which is also carried out by teams specifically specialized in such works. Depending on the work, the assembly team will also be chosen.

Art Granit offers professional services for the processing and maintenance of natural and composite stone surfaces. The technical solutions, substances and materials used by Art Granit are in accordance with the current international requirements, complying with the highest international standards precisely to extend the life of the stone.

We are proud of the work we do, in the given case with the kitchen countertops, because our countertops, the ARTGRANIT brand, have an antibacterial surface, are durable, resistant to acids and salts, impact and scratches, and have an extraordinary design and most importantly - they are easy to maintain.

Back to list

Back to list

Elaborarea siteului - ilab.ro

Elaborarea siteului - ilab.ro